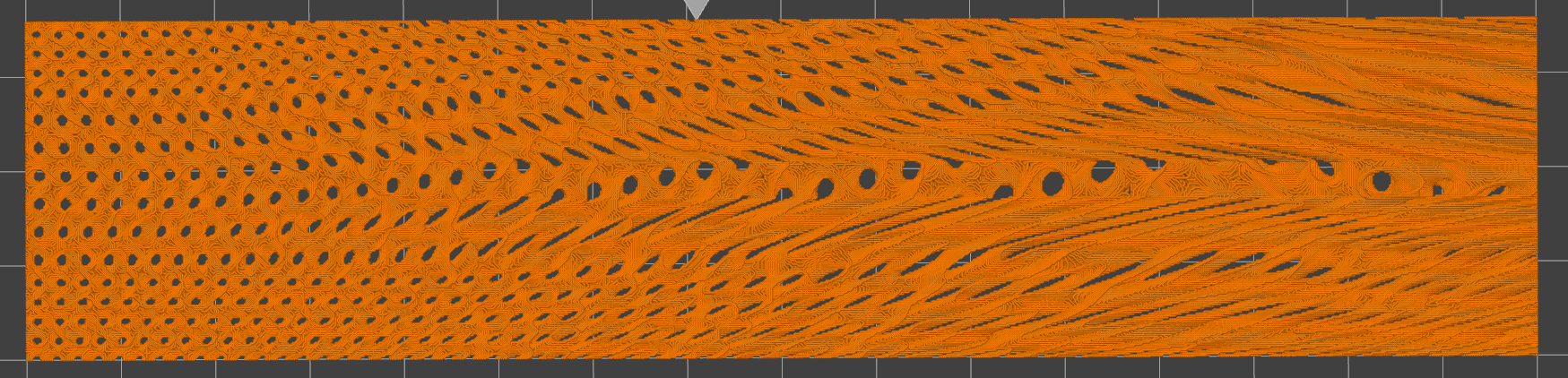

The infill structures inside most FFF 3D printed parts are printed with a single constant density for the entire model. This leaves an excess material in some areas and leaves others poorly supported. Our method generates lattices that smoothly transition between different density values, creating infill structures that can be tailored for each unique use case.

While other methods can create variable density infill structures, our approach maintains a constant wall thickness throughout the structure as opposed to thickening the walls of a tessellated cell. This gives our approach advantages particularly for deposition-based processes, since the tool will never have to retrace a path to increase the thickness.

These structures can be generated with little additional user input, making the process easy to integrate into existing path planning workflows.

Primary Researcher:

Isaac Wegner, Master's Student Exp. Graduation June 2025

wegneri@oregonstate.edu

https://linktr.ee/isaacwegner

Advisor:

Dr. Matt Campbell

matt.campbell@oregonstate.edu

We’re looking for collaborators and sponsors who want to shape the next generation of additive manufacturing system.