Innovations in 5-axis 3D printing expand the potential capabilities of additive manufacturing to include processes such as modification and repair. The ability to change the orientation of the tool allows for printing on complex surfaces. While convex surfaces are straightforward, concave surfaces risk collisions between the printer and the part. This research uses two different methods to prevent collisions, first by altering the geometry of the printed region, and second by altering the angle of individual points along the print path.

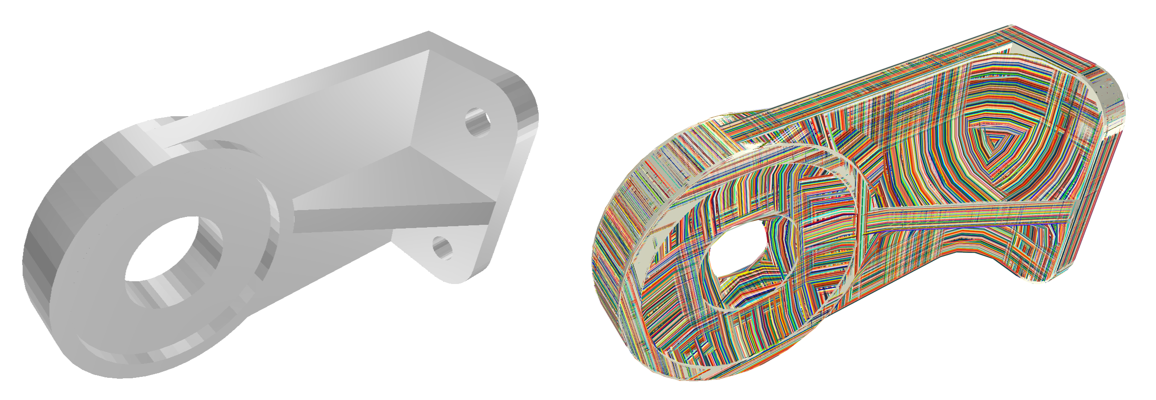

The first method is to determine regions that the tool cannot reach. The desired print region is refined to remove the unreachable regions, resulting in a solid that can be printed. The settings for determining the exclusion zones defined by the print surface are given by the user, so they can be edited to fit the current machine specifications. An example of a potential print surface and the calculated exclusion zones are shown below.

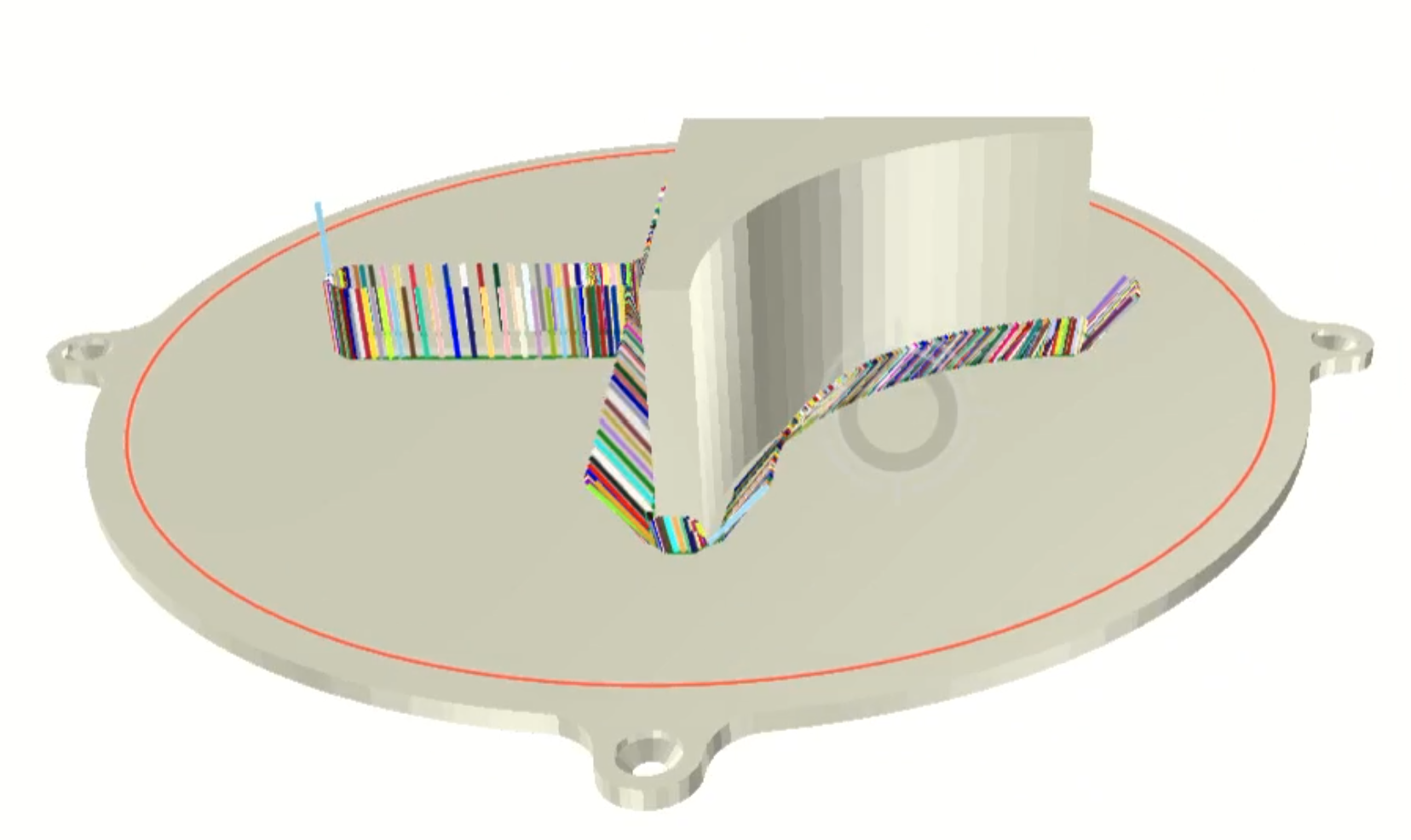

The second process is to determine the print nozzle orientation for points along the path. While traditional 3-axis printers always print normal to the print surface, we can control the orientation of the nozzle to allow us to print further into concave regions. This is done through a similar method to the region refinement, where intersections between the solid (simplified to offset polygons) and the nozzle (simplified as a cone) are used to find the best orientation. These help us to approximate the space that the tool takes up, allowing us to determine the print orientation. An example of a part with print path orientations is shown below.

Primary Researcher:

Sam Elliott, Master's Student Exp. Graduation June 2025

elliosam@oregonstate.edu

www.linkedin.com/in/sam-a-elliott

Advisor:

Dr. Matt Campbell

matt.campbell@oregonstate.edu

We’re looking for collaborators and sponsors who want to shape the next generation of additive manufacturing system.